The producing landscape is consistently evolving, and automation is for the forefront of this transformation. particularly, automatic liquid filling is revolutionizing industries by enhancing effectiveness, precision, and In general productiveness. Choosing the ideal liquid filling equipment available is essential for organizations trying to continue to be aggressive and fulfill the growing calls for of the industry. This information will discover the most recent innovations in liquid filling machines, spotlight the value of picking out the correct manufacturer, and supply direction on selecting the great product for your unique sector software.

Table of contents:

improvements in Liquid Filling Machines: What foremost suppliers offer you in 2025

Why picking out the suitable Liquid Filling Machine Manufacturer Impacts Your Output high-quality

Liquid Filling device available: Which product matches Your business Application greatest?

improvements in Liquid Filling click here devices: What major companies give in 2025

Leading liquid filling machine producer are regularly pushing the boundaries of technology, introducing modern attributes that improve functionality and performance. one particular vital trend is the integration of Superior sensor technological innovation, enabling actual-time monitoring of fill degrees and automated changes to keep up accuracy. A further sizeable innovation is the event of far more functional equipment that can cope with a broader number of liquid viscosities and container dimensions, reducing the need for a number of equipment. Improved cleansing and sterilization systems also are getting prominence, specially in industries with strict hygiene necessities. On top of that, producers are incorporating sensible technologies, letting for remote checking, diagnostics, and predictive upkeep, reducing downtime and maximizing productivity. The use of robotics and automation is usually on the rise, enabling completely automated filling traces with minimum human intervention. When evaluating different machines, take into account these improvements and opt for a model that incorporates the latest engineering to enhance your output processes.

Why Choosing the Right Liquid Filling equipment maker Impacts Your Output high quality

deciding on the correct liquid filling equipment company features a profound impact on your output good quality. A reliable company not simply gives higher-high-quality machines but also offers expertise, help, and a dedication towards your achievements. A top rated-tier manufacturer will do the job intently along with you to be aware of your unique requirements and propose essentially the most proper remedies. They will give custom made equipment configurations to improve your manufacturing procedures and ensure consistent, exact filling. Furthermore, a trusted maker will present in depth coaching and complex support to guarantee your machines function efficiently and proficiently. within the occasion of an issue, they can deliver prompt and reputable restore companies to reduce downtime. By partnering by using a trustworthy company, you attain entry to a prosperity of knowledge and experience that will help you increase your solution high quality, lessen squander, and improve your overall operational effectiveness. It’s crucial that you contemplate things such as certifications and marketplace standing when producing your conclusion.

Liquid Filling equipment on the market: Which design matches Your field Application finest?

locating the perfect liquid filling device available for sale necessitates mindful thought of the specific marketplace application. distinctive industries have various wants, and The perfect device will differ based on the kind of liquid becoming filled, the container dimension, and the specified production level.

prescribed drugs: involve machines with substantial precision, sterilization abilities, and compliance with rigid regulatory benchmarks. Aseptic filling devices are frequently essential.

Cosmetics: need machines that keep aesthetic charm and forestall spills. exact quantity Command and Light managing are critical.

foods and Beverage: require equipment which are simple to scrub and sanitize, frequently demanding stainless steel development to satisfy hygiene needs.

Chemicals: Necessitate equipment made from corrosion-resistant components and Geared up with safety functions to protect workers.

private treatment: gain from functional devices which can handle a number of liquid viscosities and container designs.

Before making a obtain, diligently assess your particular requires and go with a product that may be tailored in your industry software. take into account components which include filling precision, pace, versatility, and ease of routine maintenance.

the way forward for automatic filling is shiny, with innovations consistently increasing efficiency and accuracy. By carefully analyzing your preferences, choosing the correct liquid filling device available for purchase, and partnering having a reliable liquid filling equipment producer, you'll be able to optimize your output processes, improve your output high-quality, and reach sustained achievements inside the aggressive marketplace. Embrace automation and spend money on the way forward for your business today.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Hailie Jade Scott Mathers Then & Now!

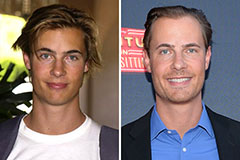

Hailie Jade Scott Mathers Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now!